- A single smartphone efficiently controls six robots in the pottery factory, enhancing productivity.

- The automation allows workers to focus on more skilled tasks by taking over heavy lifting operations.

- An investment of over $150,000 in Automated Guided Vehicles has significantly reduced labor needs and costs.

- The production capacity nearly doubled from $7,000 to $14,000 per day, emphasizing financial benefits.

- Transforming clay to pottery now takes only ten minutes, a drastic improvement from three days.

- Other local businesses are adopting similar technologies, improving overall quality and reducing waste.

- Shuanglong aims to produce 300,000 pieces by 2025, enhancing its market position.

- Embracing technology is vital for thriving and leading in the industrial sector.

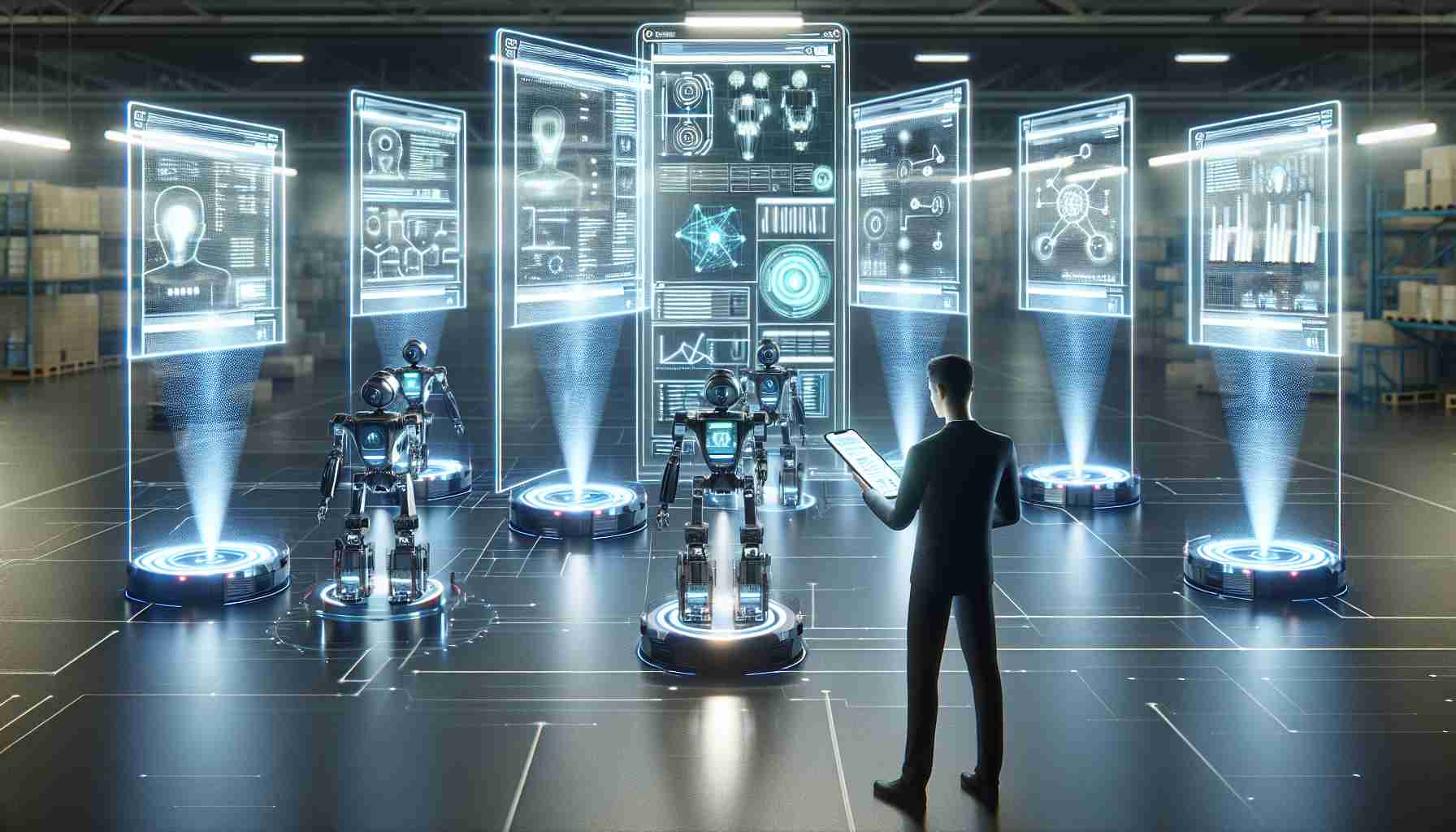

In a remarkable display of modern technology, a single smartphone orchestrates the work of six agile robots, capable of lifting 200-kilogram ceramic pieces in a bustling pottery factory. Welcome to the transformative world of smart automation at Shuanglong Ceramics in Ziyang, where the once labor-intensive task of manual handling has been revolutionized.

Imagine a scene where clean, sleek robots glide effortlessly along pre-defined paths, expertly gripping clay pots and transporting them to their designated spots. Workers now manage these machines from their phones, effortlessly overseeing operations with just a few taps. One worker, relieved from the drudgery of pushing heavy carts, praises the efficiency of these robots, which take on the heaviest tasks, allowing him to focus on other responsibilities.

The company invested over $150,000 in cutting-edge Automated Guided Vehicles (AGVs), cutting labor needs by twelve people a day and slashing costs. With the integration of smart technologies, the production capacity soared from $7,000 to an impressive $14,000 a day, and the time to transform clay into exquisite pottery plummeted from three days to just ten minutes.

As other local businesses adopt similar digital innovations, they’re not only enhancing production but also increasing quality and reducing wastage—setting the stage for Ziyang to become a beacon of efficiency in the industrial sector. By 2025, Shuanglong aims to produce 300,000 pieces, solidifying its position in markets domestic and abroad.

The lesson here? Embracing technology isn’t just about keeping up; it’s about thriving and leading the charge into the future.

Revolutionizing Pottery: The Future of Automation in Manufacturing

Smart Automation at Shuanglong Ceramics

In an inspiring shift towards smart automation, Shuanglong Ceramics in Ziyang has successfully integrated advanced technology into its operations. A single smartphone now manages the routines of six agile robots that can lift impressive loads of up to 200 kilograms, fundamentally changing traditional pottery production processes.

Key Innovations in Automation

The notable investment of over $150,000 into Automated Guided Vehicles (AGVs) has not only reduced labor requirements by twelve workers each day but has also doubled the company’s daily production capacity from $7,000 to an astonishing $14,000. Previously labor-intensive tasks have been streamlined, cutting down the time to convert clay into beautifully crafted pottery from three days to a mere ten minutes. This transformation underscores a broader trend in manufacturing where efficiency, speed, and quality significantly improve through technological advancements.

Market Impact and Future Trends

As Ziyang continues to bolster its position as a technology-forward industrial hub, the trend toward automated production methods will likely proliferate among local businesses. This movement not only enhances productivity but also elevates product quality and minimizes waste, setting a standard for operational excellence.

Essential Questions About Smart Automation

1. What are the key benefits of implementing AGVs in manufacturing?

AGVs provide several advantages, such as reduced labor costs, increased production speed, enhanced safety, and better inventory management. They minimize physical strain on workers by taking over heavy lifting and transportation tasks, thereby allowing human employees to devote time to more complex activities that require critical thinking and creativity.

2. How does smart automation affect employment in traditional industries?

While there may be concerns about job losses due to automation, the net effect can actually lead to job transformation rather than elimination. Workers are often retrained for more skilled roles, focusing on technology management, maintenance, and quality control, ultimately driving innovation and growth within the sector.

3. What is the outlook for the ceramics market with the rise of smart technologies?

The integration of smart technologies in ceramics and related industries is projected to grow steadily. By 2025, Shuanglong aims to produce 300,000 ceramic pieces, signifying a strong commitment to harnessing technology for scaling operations. As industries continue to innovate and adopt smart solutions, we can anticipate a significant enhancement in overall market competitiveness.

Additional Insights

– Use Cases: The implementation of automation in pottery production can be replicated in other sectors, from automotive manufacturing to food processing, indicating a versatile application of robotic technologies.

– Sustainability: The move towards automation also leads to reduced energy consumption and lesser material waste, aligning with modern sustainability goals.

– Market Analysis: Automation is predicted to grow, with an expected global robotics market valuation reaching billions by the next few years, driven by industrial demand for efficiency and precision.

For more insights on the automation revolution, check out Automation World.